When it comes to all wedge things, most reasonable people can agree that Bob Vokey of the title is the chairman of the board.

Last summer, MygolfSpy’s Rick Young asked Vokey where he thought the future of the wedge would go.

“We’re always seeing new materials,” Vokey said. “But, honestly, nothing has come yet to replace 8620 carbon steel. It’s a cast, lasting, you can grind it … We stay with it because it’s not broken.”

When Boeing Smith, a doctoral level metallurgist who admits to a lifelong chip on the shoulder, read that all he could do was just smile.

He was, after all, in the process of replacing irreplaceable and disrupting what was not broken.

Smith, you see, works to Golf ClevelandAnd he is the boy behind the new wedge material of Cleveland, Z-Alioy.

Believe us. This is a story you want to hear.

Zen i z-alien

At the age of 64, most people I meet look like children, but Boeing Smith, at the age of 31, looks a little younger. Don’t let his Opie Taylor behavior deceive you anyway. Smith is a high search engineer in Cleveland with bachelor degrees in physics and chemistry along with a master and PhD in metallurgical welding/engineering.

His doctoral project included the rigidity of metals, strength and resistance to coating to impact resistance, which, if you think of it, is an important type when it comes to golf clubs. Oh, he has also been as low as a handicap Plus-2.

The guy is directly from the central casting.

Smith joined Cleveland Three years ago and a very specific task was immediately assigned: Find a wedge material that is better than 8620. He met with engineering, marketing and product development teams, asked many questions and took many records.

“They asked for things like forgiveness,” says Smith Mygolfspy. “But how do you make something more forgiving? You move the discretional weight. This translated into density. They also wanted it to feel really good. That meant that the material had to be softer.

“They also wanted her to last a good time. That meant it had to be stable.”

From those meetings, Smith developed criteria and began to shoot for a wedge material that can beat 8620.

What is behind the door no. 3?

Smith reported again that he found three materials that could work.

“One of them was from the oil and gas industry. It beat 8620 in as three categories. The second was from airspace and beat 8620 in four categories.”

The last material, however, beat 8620 in every category, hands down.

“They asked me,“ Where is it? “I said, ‘There is not yet.

For a child who grew up in spongebob and Hey! ArnoldHe does not lack faith.

Also, do not think of a minute that Smith went to the path of artificial intelligence to develop Z-alioy. He did it in the old fashion manner. He dug in his textbooks.

“Some of my books look like Harry Potter Prince half blood With all the notes and highlights. “

So how does it go for the creation of a non -existent material? Again, Smith began by asking questions.

“I wondered what a plane crashes and what breaks a pipeline? Does a golf club break the same? In some cases, the answer is no. So then can I trade what a plane crashes, but it doesn’t break a golf club to check every box?”

Z-alien alchemy dichotomy

Smith and his team tried to create a seemingly unstable material material. It had to be gentle to feel but difficult for durability. It also had to be low density to create discretional weight, but also strong enough for casting, grinding and bending.

And the change from the change would be fine.

“Chemistry and physics in which you manipulate things such as tenderness and endurance are not completely exclusive mutual,” he explains. “There were some numbers that I couldn’t go back too far or otherwise I could grab things.”

Smith would not dive too deep into the metallurgy of all (the patent is pending), but it confirmed the lowest density of the spared material about six grams in discretion. In designing the Golf Club, the new discretionary weight always comes with an exchange, so when the wedge design team asked what to give up to get those six grams, Smith smiled and said, “Not free. Move wherever you want.”

Z-alien rusty characteristics are also related to durability. We have said it so many times already, but once again it will not hurt. Rust does not add rotation. Raw wedge faces, unsaturated can Improve rotation. It all depends on who you are doing.

Rust is erosion and erosion is bad for ear resistance.

“Carbon can control some properties in steel,” he says. “I called it where I could control the density and wear the resistance. I phoned in other elements separately as I know how high I could go where they would not be catastrophic when joining them.”

Sustainability and Solution 87 percent

Soft AND Durable?

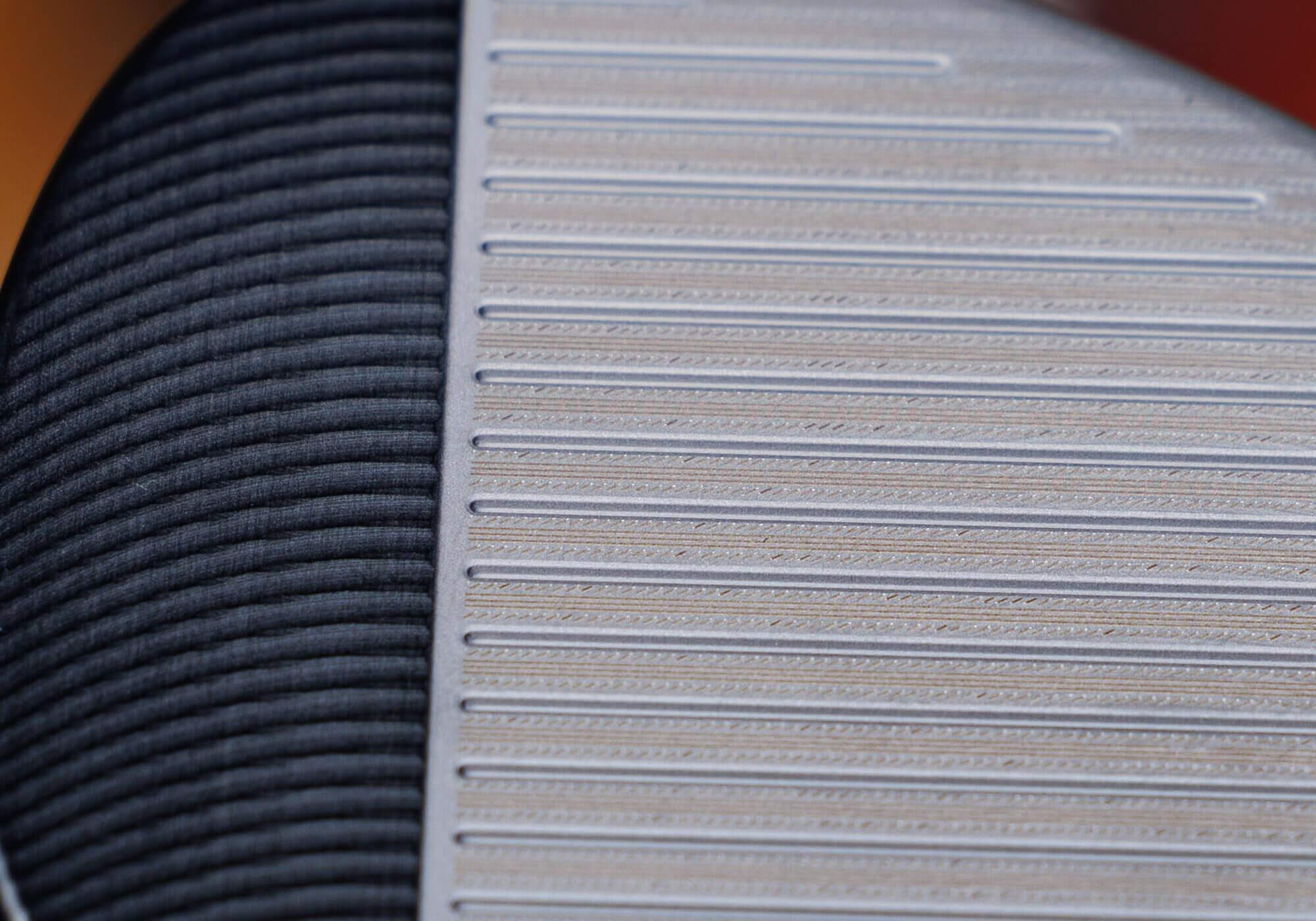

Yes, that’s what Cleveland is saying. Despite felt softer than 8620, Smith turned enough diats to make Z-alioy more durable when it comes to groove dress. After the prototypes were made, his team did several tests of the players side by side with the previous wedges of Cleveland Raw 8620.

“We did the trial with three wedges of Z-alien and three 8620 wedges. These were made in the course with real players hitting all sorts of shooting. We got ordinary scanning before and after the groove dress was 87 percent higher with 8620 wedges.

“The results were pretty surprising, but the research department said,” We don’t trust you. Exit and do it again. “We did and got the same results.”

Cleveland She says her pro Tour staff approved RTZ wedges faster than any other new product in the last memory. As for the dress, Brooks Koepka normally replaces his lobe wedge every month. His first RTZ stayed in the bag for more than two months.

Traveling to Z-Alioy was not always quiet

It is important to repeat that Z-alioy is a really new material. It’s not that it was just never used in Golf. Has not been used More Before, everywhere.

At least on this planet.

“This is not a military grade and is not the rate of airspace,” Smith says. “Grade Golf. I would never put this material on a plane or a pipeline. I would definitely put this in a golf club.”

From the beginning to the end, Smith estimates that the project lasted three years good, most of this spent working 60 hours a week. He got the material right quite early with the help of Cleveland Rick engineers also begins Jake Grenier but the road to the first time was a little Bumpier.

“There were times when we have wondered if we have to pull the outlet for all this.

While the material itself is unique, do not expect him to find his way in custody. lily was only optimized for wedge.

“We traded many other things,” explains Smith. “It’s not like we just pour this chemistry together and a magic material comes out. We make the formula to process it specifically for wedge.”

Smart is so smart

Despite the degrees in physics and chemistry and a master and a doctorate in welding engineering and metallurgy, Smith does not consider himself a “smart” boy.

“My brother is actually smart in the family. There are really smart people in this world and then there are great lazy people who look smart. That’s me.”

Smith won his doctorate in Ohio state, home for one of the only two welding engineering programs in the world (the other is in Japan). He solved his doctoral problem in just three years compared to five considered normal.

His professor was not pleased.

“The problem was that I resolved it very simple for a way. I found the measure of what we needed to measure, but my professor said I was not advancing the science field. That was not a PhD caliber job.”

The Academy may be anything for the process, but the real world wants results. Not interested HOW You find the answer, only THAT You find the answer.

“Like that famous quote by Bill Gates:” I give my most difficult work to my most lazy people. They will find the easiest way to solve the problem. “”

About that thing Boeing

As we approached the end of our conversation, I had to ask about Smith’s first name. After all, he is the first person I have ever met with the name Boeing.

“My father’s name was David Smith and he grew up in every bad checklist in the world. He said,” If my children have good credit or bad credit, everyone will know him. “He was in aviation, so my name is Boeing.

Smith grew up in the small town of Galipolis, Ohio (Pop. 3,413) on the Ohio River near the borders of Western Virginia and Kentucky. He says he is one of the poorest areas of the country, which partly constitutes the great chip he carries on his shoulder.

During his first class as a beginner college at Whittenburg University, the professor asked everyone to introduce themselves and say where they are from.

“I said,” I’m from Galipolis, Ohio. “This person returned to me later and said, ‘Good luck. I already had a chip on the shoulder.

Boeing also became a university legend when he catalogs the local drink store with the amount of alcohol per dollar.

“You don’t have a lot of discretionary costs in college. It is a very simple formula.

Solving a problem we didn’t know we had

Creating a wedge material better than 8620 steel carbon steel is probably not on anyone’s 2025 bingo card. As Bob Vokey said, it’s not broken, so is the goal?

There are two answers to this question. For Smith, it was just a problem he was given to solve. As a metallurgist, he did not worry whether he was financially applicable or even needed. Its purpose was to find a material that would be softer and more durable than 8620 and would not rust.

For Cleveland, it is a bigger question and a greater risk. Why change something if it works well? With Vokey the fugitive market leader, Cleveland continues to remove it with Callaway and Taylormade. However, the old axiom says if you continue to do what you have done, you will continue to get what you got. If you are ClevelandGetting that special Apple cart is a risk worth taking.

“You get into the unknown and if swelling, it’s a kind for you,” says Smith. “It was very stressful because there were times when it was not working and some tests failed. Looking back, though we are happy to go for it.”

With a deplorable smile, he added, “Also too easy to say now.”

office Z-alien History: Has Cleveland Golf really developed a better wedge material? first appeared in MygolfSSS.