Johnny Wunder

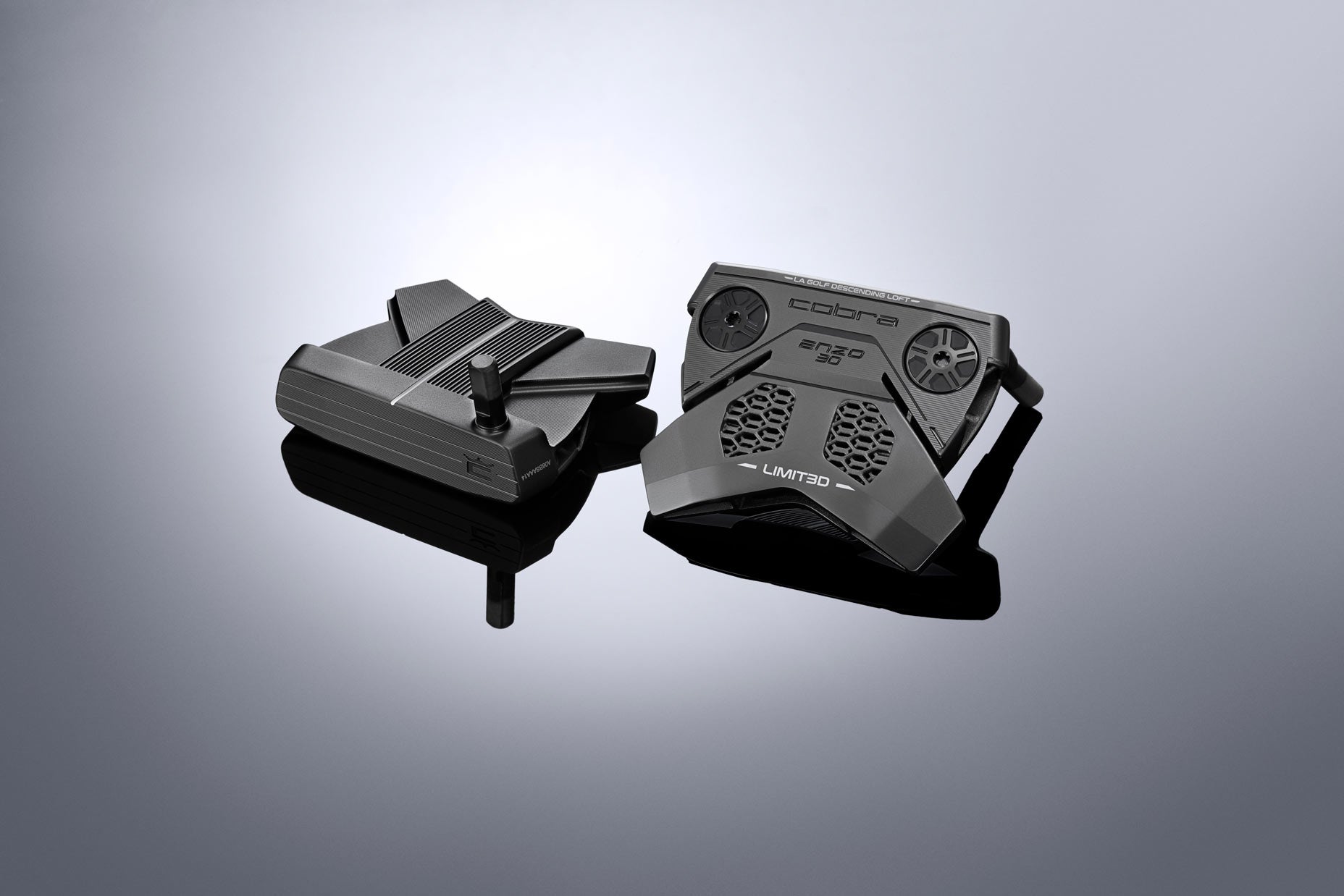

Presentation of 3DP Putters from Cobra. Enzo (goods) and track (blade) are available in limited quantities (500 each).

Courtesy

From where I’m sitting, 3D technology after connecting to a golf club has always been a “yah, one day” concept.

I remember the first time I saw something print 3D – it was probably seven or eight years ago when a 3D astronaut press a tool in space. At that time it seemed wild, until I realized that people have been 3D oppressive items for years, sending me a bunch of rabbit holes.

At no point has I ever thought that this technology would make its way to Golf, but here we are.

While many companies choose lanes to guide them in their technology evolution (Callaway and its follow -up of it for example) Cobra Golf has all gone to 3D And it is flattened with every repetition.

Cobra 3dp Tour Irons Custom

357 dollars in fairway jackey

Irons Tour Tour 3D King uses 3D printing technology to unlock a new performance field. One of their design of a kind contains the most forgiving shape of the blade on the market, giving the pardon that the aspirating players need, and the graceful images and the gentle feeling the best players want. Construction of 3D Eachdo Iron Print steel is completely 3D printed by 316 stainless steel. 3D printing provides significant advantages over traditional methods of casting and falsification, unlocking more design freedom and significant performance improvements. Forgive players Shape Blade Shape 3D printing has unlocked new design options, enabling Cobra engineers to create a compact shape of blade with massive properties (high, low CG) of an iron for improving the game without sacrificing the best views and feeling that the best players are looking for. The internal structure of the Cobra shutters took a muscle blade shape (similar in size and shape with King Iron Tour), and turned the inside of the blade into a complex interior shutter structure to reduce the weight of the club by 33%. This discretional weight was repositioned to optimize the feeling, position CG and MOI.

Buy now

View Product

Remember at the beginning of 2025, was the new Cobra staff Max Homa who placed a fully 3D’D group of muscle cuffs in the game. I’ve seen them close; They are perfect. This is the first thing you will find with anything in 3D buckets or metal-tolerance injection and club-to-club consistency is narrow as it takes.

Now comes the printed 3D putters.

presentation New Putters Cobra Golf 3dp

Three things to know

- 3D printing has opened up some new opportunities for performance lanes that I don’t even think Cobra realized at first: there is always a point where you have to cheat among weight tolerances. For example, you can design a putter with an extremely high MOI and is super forgiving, but at one point you are limited by how much that special head will weigh. So, a choice must be made to sacrifice one to please the other. With the 3D process that decision is deleted from the table. If you want to put a high MOI package in a smaller chassis, it is possible with 3D pressure. Since Cobra is producing these from a steel block, it actually allows engineers to produce their heads in the required model, train weight from a location and re-sign it wherever they like. Take for example the Enzo model, which has up to 170g replaced weight with the lattice which allowed the R&D Cobra to redistribute that front weight with zero compromise for feeling and performance.

- All COBRA 3DP Putters have the discounting technology of the attic. Made famous by SIK – now La Golf – this facial technology has four points of attic from top to bottom (four degrees up and one degree at the bottom) which allows the Putter to be optimized for players supporting their axis and those who add attic to influence.

- The only way to make the placers with these performance properties is through 3D printing. There is a new border in what is possible for the whole design of the club. The best way to describe it is the overall efficiency of production with very little compromise in the design-vs-and-shaft dilemma. Here is the manager of the COBRA SR products line. Chad Dehart: “As leader in technology and innovation, we recognized the 3D printing potential to create more advanced products, impressive performance gains will impress their performance.”

Models:

Dirty (blade)

Golf

Track-45

• Neck of the plumbers

• 45 ° Tore hang

• Complete axis compensation

• Ideal for the moderate type of bow shock

Track-60

• Small sloping neck

• 60 ° Tore hang

• ½ axis compensation

• Ideal for a great stroke. Beyond

Enzo (Mallet)

Golf

• Single Posting

• 0 ° TOE hinges – balanced face

• ½ axis compensation

• Ideal for direct, direct blow

Enzo-30

• Small sloping neck

• 30 ° Tore hang

• ¾ Axis Compensation

• Ideal for the moderate type of bow shock

Golf

For Golf Kobra:

Both Enzo and track models come standard with KBS CT Tour Putter 120 shafts and Zenergy superstroke 2.0pt grips. Only 500 units of each new Limit3d Putter ($ 599 each) are available for online shopping and selected retailers. For more information or to buy a limit3d Putter, please visit www.cobragolf.com.

Want to fix your bag for 2025? Find a suitable location close to you in real golf.

Johnny Wunder

Golfit.com editor

Johnny currently serves as director of equipment at Golf.comcontributing to platforms like fully equipped golf. Prior to this role, he was the content marketing manager at the Callaway Golf, where he led “The Wunder of Wunder of Callaway Golf”, a platform dedicated to the in -depth content of golf equipment. Before entering Callaway, he was the director of the original content and host of Podcast “The Gear Dive” Golfwrx.com. Beyond his professional efforts, Johnny is a golf player thirsty with a deep passion for the game after playing since his youth in Seattle, Washington.