For years, golfers have debated whether forged clubs are better than their counterparts.

Our data-driven testing at MyGolfSpy has proven that it does little or no difference in performance between the two. The ball doesn’t know (or care) if a club is faked or dropped.

But what we haven’t explored yet are the differences between forged and cast clubs on a granular level.

Until now.

What if we could put a forged and cast club under an electron microscope and understand (literally) on a microscopic level WHY a golfer might prefer one over the other?

If the consensus is that forged clubs “feel” better, is there any real material evidence for this or are we just buying into the constant marketing hype created by every major manufacturer? Said another way: If we look under the hood of a forged and cast club, are they really that different or is it all in our heads?

This is not your typical “counterfeit vs. discarded” item. There is no Forecast data and definitely no subjective feedback. This is the most in-depth, up-close and accurate look at the changes in the material construction of these clubs, down to their grain structures and crystal orientations.

For the golfer looking for an extremely thorough and deep dive into this, read on. For the golfer looking for five ways to get after examining forged and cast clubs under an electron microscope, you can skip to that section here.

Before we dive into both, it’s important that you understand the actual process of observing through an electron microscope. The process by which the microstructures of forged and cast sheaves are analyzed is called EBSD, electron backscatter diffraction.

What is EBSD?

According to Ametek, “Electron backscatter diffraction (EBSD) is a key analytical tool for crystallographic microstructure characterization in the materials and earth sciences. The EBSD technique uses a scanning electron microscope to collect statistical data on grain size, orientation, grain boundary character, and structure, which are critical parameters in determining the mechanical properties of crystalline materials.

In layman’s terms, EBSD is a technique that allows materials scientists to understand how metals react to various processing steps. Its applications include industrial engineering, automotive engineering and more.

Here is a quick example why behind EBSD. Say an industrial engineer is trying to figure out what material to build a footbridge out of. Looking at the microstructure of the metal gives a clear picture of the material and its potential weaknesses.

Put even more simply, EBSD is an essential component of quality control and materials development.

The process itself is complex and requires extensive sample preparation. And, of course, access to an electron microscope. Seeing as I have neither the access nor the expertise to perform an EBSD analysis, I reached out to a family friend to help.

After a lengthy analysis of a forged and discarded golf club, we have come to some interesting conclusions.

1. Throwing is unstable

The actual process of swinging a golf club seems simple enough. The molten metal is poured into the mold and cooled. But the problem is that how quickly or slowly the metal cools has a direct impact on the grain structure and, therefore, on the crystallographic orientation of the material.

“The final structure will depend strongly on that cooling rate,” Matt Nowell said. EBSD Product Manager at EDAX.

“When it (the metal) first solidifies from a liquid, it forms a kind of crystal. But as it cools further to ambient room temperature, it transforms into another crystal. So what you’ve got going on is that the initial crystals that form after casting and cooling are essentially too large. But when it cools further and they turn into this second phase, they have these smaller grains that occur. It’s just because there’s a difference in the way the atoms are arranged from one crystal to another.”

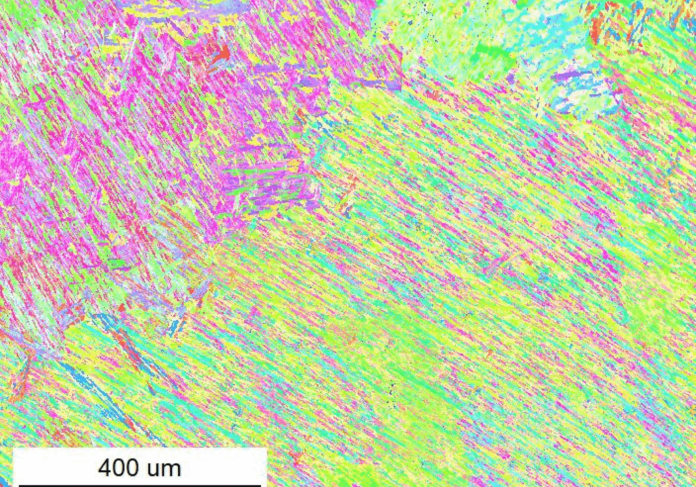

A quick look at the electron microscope image of the melt face gives a detailed picture of this discrepancy.

What you see here is a scan of the crystal orientation of the fusion face. You’ll notice that the top left of the image is completely different, which means the orientation of the crystal is different. Notice how random it is? This is because the crystal orientation, and thus the grain size, depends largely on that cooling process.

“It’s going to be random however it solidifies.” Nowell said.

In contrast, a look at the crystal orientation of a forged club face provides a pattern of consistency.

Note that the crystal orientation is consistent throughout. It is easy to see that the grains are smaller and more compact. This, too, has an impact on the integrity of the material (we’ll talk about that in a second).

The reason the forged club face is so durable is because of the repeatability that comes with the forging process. No cooling, no heating. The metal is pressed in the same way over and over again, leading to consistency on a crystallographic level from iron to iron, set in solidification.

“For forgery, it’s much easier to understand and predict if you’re always pressing a piece of metal over and over again. crystals in metal will have a more consistent response. They’re going to bend the same way every time,” Nowell said.

“No matter how you forge the structure, you’re going to get this kind of final crystal orientation. So I think a set of forged clubs will end up being more durable.”

2. Smaller grains mean stronger metal

The rate at which the material cools has a direct effect on grain size. The faster the material cools, the smaller the grains. However, cooling too quickly can cause the material to become brittle.

This is for casting. Molding essentially provides a smaller grain structure, as seen in the images above.

“As your grain size gets smaller, that means your metal will be stronger. And I think that was not entirely unexpected.” Nowell said.

So why not cool the casting batches at a faster rate to make the grain structure smaller?

“If we’re just thinking in terms of trying to match the performance of the forged club by going to a smaller grain size, that would be helpful. The downside to this is that it can make the material much more brittle. So it might not be able to withstand the impact,” Nowell said.

The pictures above show the clear difference in grain size. Remember, the smaller the grain, the stronger the metal. As such, forged bars are more resistant to warping or breaking, so they can bend to various lies and lofts without snapping like a thrown club.

3. The feel is a result of the way the sound travels through the metal

When we talk about how a golf club feelswe are often referring (subconsciously or not) to how it is sound when hit.

Most golfers agree (though I’m not convinced) that forged clubs feel better than cast clubs. Adjectives often used to describe counterfeit clubs are “soft”, “buttery” or “quiet”.

The way vibrations (or sounds) travel through the club is a direct result of the grains and their associated boundaries.

“It’s interesting because of the propagation of the sound through the metal. That acoustic energy is also a function of crystal orientation and so, having different orientation distributions and generally different textures (how these orientations are created either through casting or through forging), can help explain why they will feel otherwise,” Nowell explained.

“(They feel) different because the sounds are going to be different and those vibrations are going to travel differently through the clubs and some of that is dampened by the grain boundaries.”

Summary: Forged vs. Dumped

- Casting is inconsistent, forging is consistent

- Smaller grains make the metal stronger. Forged clubs have smaller grain structures.

- The feel is a direct result of how sound travels through the grains. The different grain structures between cast and forged sticks will result in a difference in “feel”.

What can we conclude?

If you’re trying to get me to say that forged clubs are better than cast ones, you’re going to be disappointed. What I can say for sure after learning from my friend Matt is that the forging process is more consistent from a quality control standpoint.

Just like us evaluate golf balls in our Ball Labproduction quality is important to performance. So while a forged club may not “perform” better than a cast club in the typical sense, a forged club will most likely be more consistent, iron-to-iron and set, on a material level. than its cast counterpart.

“It makes sense to me how the forging would add stability to the overall behavior of the metal, like a golf club.” Nowell concluded. “If you wanted a recognizable microstructure from one set to another, forgery would give it to you.”

Post Under the Microscope: Forged Versus Cast appeared first on MyGolfSpy.